Electrics / Batteries

Latest Battery 2017

I bought a Turnigy Graphene Lithium battery as the main battery for the Schnellboot, this is 14.4 Volts and 10,000 milliAmpHours.

It's big and weighs nearly 1 Kilo (2.2 pounds) but wow this should keep everything going for a little while!

Why does it come in a cloth pouch and a fancy box with a magnetic catch, that's just plain stupid, just puts up the price and wastes the world's resources!

The rest of this page below is a historical page starting from the oldest stuff at the top (circa 2000) and the latest at the bottom but needs to be updated with the latest batteries since 2006.

I have tried many different batteries in the boat, I started with 7.2Volt 1200mAH Nickel Cadmium (NiCD) packs as I had these from my constantly breaking electric Aeroplane - hence the move to boats!

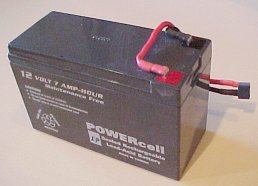

I increased the battery size to a 3AH rated 12Volt Sealed Lead Acid Battery which gave around 10 minutes of operation at full throttle with two 480 sized motors in series. This battery weighs 1.5 Kilograms (3.3 lbs).

I increased the battery size again to a 7AH rated 12Volt Sealed Lead Acid Battery but at 4.5Kilograms (10lbs) it was just too heavy for where it is fitted in boat 1. If I could move it forward a couple of ribs it would probably be OK but it's also a bit too tall.

This new battery is longer than the 3AH that I originally used so I had to build a larger battery box and also provide a cutout in one of the superstructure rib sections to allow for the extra battery height.

With current's of around 30 amps continuous and much higher peak currents per motor and with huge battery capacity we have a very real risk of fire. It is extremely important that cables have sufficient cross sectional area (12 gauge recommended) and that all terminations are ultra low resistance and well soldered, they need to be kept well apart and well insulated with good quality (Polyolefin) heat shrink tubing. If you are not sure about the rating of your speed controller, don't use it with these batteries! not all controllers can handle the 14+ volts from lead acid batteries when fully charged!

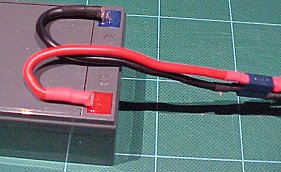

I found these 'Super Deans' plugs and sockets that are used on high performance electric cars. They can be mounted back to back very easily if you need a power take off while maintaining a high current power feed through. There is no hole through the solder terminal so they need to be butt jointed to the cable with high quality soldering. I recommend 63/37 (Tin/Lead) Eutectic rosin cored solder but if you can't get that then 60/40 will have to do. Flatten and 'fan out' the end of the cable before soldering to get more area in contact with the connector tab. You need to hold both the wire and the plug down somehow because the heat travels a long way up 12g wire and if you hold the wire with your fingers, well you know what is going to happen!

I found some great low cost, in line, fuse holders at the local Auto parts store that have solid crimped terminals onto (stiff) 12g wire and fitted them with 30A fuses, wire is a bit stiff though.

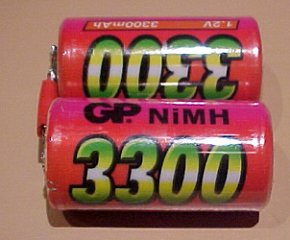

The First NiMH Battery Packs

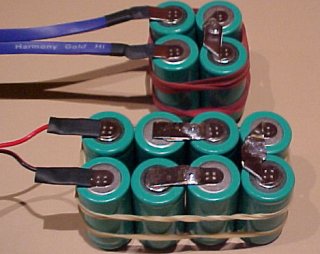

These 3000mAH (3AH) Fast Charge / Fast Discharge sub C size nimh batteries (loose cells actually) came from Batteries Wholesale for around $USD3.00 each and they came with welded tags so you can make up packs yourself (very carefully of course as these are very high energy cells and can represent an explosion risk if shorted).

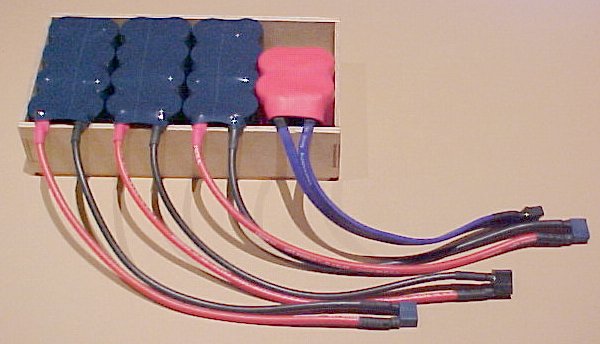

I used some Deans 12G "Wet Noodle" silicon covered wire (excellent) and 'Deans Ultra' plugs and sockets from www.offshoreelectrics.com and some 60mm diameter (92mm wide) very thin wall heatshrink from Eastern Hobbies in Melbourne (Australia) and made up the packs using rubber bands to hold them in place!

Of course there are numerous suppliers around the world who will make up packs for you and Offshore Electrics (USA) will even make them with Deans Ultra sockets and higher capacity (3300mAH) cells but Batteries Wholesale are local here in Australia (and ship world wide) so the freight cost and timing was better for me.

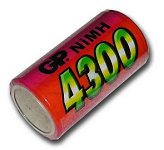

The best sub C cells found so far are the GP4300's or the IB4200's at over 4 Amp Hours or SAFT cells with the highest peak current rating - 100A - that I have yet seen in a NiMH.

Next - how to charge these beasts rapidly - I may have to design a charger, although they are starting to come down in price and again Batteries Wholesale have an improved version of the "Swallow" charger for less than US$100 and this can do NiCad, NiMH, Li-Poly, Li-Ion and sealed Lead Acid batteries. For now I have made up a simple current source using an LM317, 3 terminal voltage regulator and a resistor (and a heatsink) and powered that from my bench power supply (40V) so I can charge the batteries at 1/10 C or 300mA for 15 hours. I have some Philips silicon temperature sensors that we use commercially in a computer fan controller and I have experimented with these as a way to monitor the cell temperature easily, that looks very promising! Measuring the temperature rise of cells is one of the recommended ways to tell when they approach the fully charged condition.

With any new battery pack made up of individual cells in series (no matter what it's chemistry) it is very important to trickle charge them for a longer time (20 hours or so) the first time to make sure that all cells are absolutely fully charged, because if you fast charge them you will end up with some charged (and heating up) and some not fully charged and then when they are being used you have a very real risk that one or more cells in the pack will fully discharge first and as the other cells push current through them they will reverse polarity and then they may be permanently damaged. And of course you 'should' buy matched cells for the same reason, however an over-riding recommendation for NiMH cells is not to fully discharge them anyway, they don't have a memory effect like NiCD cells (some are starting to dispute this) so you can charge them at any point, even if they are half full.

NiMH cells apparently don't like being hot and the amount of total energy available from a battery depends on the discharge current/time (lower is always better) so I decided to use one battery pack for each of the three motors in the boat, this limits the current flow to safer levels, should extend the life of the battery cells and should give a longer duration run. I also have a single shared 6 cell pack for reverse on the outside or wing motors and I have made a late change to the triple speed controller to use the reversing battery for the BEC (Battery Eliminator Circuit) to power the receiver and servo's as this battery is not used in fast forward and is in fact trickle charged by slow forward speeds. So you can accidentally run the main batteries to flat and maybe still have the ability to get home backwards!

Thought for the day, an ATX PC power supply has a +12Volt output at around 20 to 30 Amps and is a very inexpensive power supply and it already has a power inlet and often a power switch! Shorting the slim green wire to any black wire on the ATX plug will turn them on!

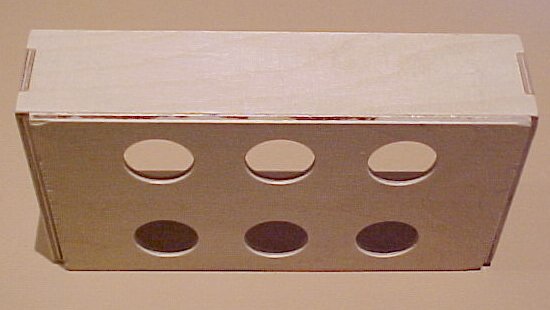

I had to build a new battery box that I fitted between ribs 14 and 17 of Hull-1 and I also made some twin vertical rails that sit in front of the battery box forward to rib12 for the speed controller to screw on to so I can get to the controls and plugs. I may consider moving all this weight forward one rib in the current boat design to improve it's weight balance but it is pretty good where it is, it may be just possibly a bit low in the water at the stern.

I did (since this photo) increase the small reversing pack to 6 cells, (30 cells total) this gives a total battery weight of around 2.5 Kilograms (5.5 lbs) for a total forward capacity of 9AH and reverse of 3AH and that's a pretty impressive improvement from the Lead Acid batteries.

The new Hull-1 battery pack configuration, these are sub-C size high performance, high rate charge and discharge, 3000mAH NiMH cells at 1.2V each so the overall battery is 9.6 Volts at 3 Amp Hour capacity. Fully charged it measures around 11.5 Volts and for longest life they should not be fully discharged or they will lose capacity, apparently due to irreversible chemical reactions..

WARNING ** DO NOT USE any old NiMH cells for high discharge currents - these MUST be a specific type of cell.

DO NOT accidentally or intentionally short these cells or battery packs, they may explode!

These cells are designed specifically for industrial applications. Regular domestic use cells will overheat, may rupture and could explode.

The Later Hull-2 Battery Packs

I had issues with the 3000mAH cells that I fitted in Hull-1, they were fitted with welded steel tags and I left them on and merely soldered them together. After a short while of high speed running the temperature of the tags got so high that it melted through the thin heatshrink tubing. I have also proven that these cells are not very good anyway and at reasonable currents some cells are reversing polarity which is probably not doing them any good. So I sought some advice from the serious airplane guys and was told that GP brand cells are the only ones worth considering unless I wanted to go for Lithium Polymer batteries. So I bought some GP3300 cells and made up some battery packs using Deans 12g wet noodle wire to interconnect them and when tested, sure enough these batteries can supply 30 amps and not really get warm and their cell voltage stays above 0.95V at this sort of current, I also increased the pack to 10 cells (12V nominal) to get more power out of the AXI Brushless motors in Hull-2. I have tested a 12 cell pack also but my 40A controllers may not like that long term, particularly if I hold the boat back in the pool but I do now have the 80A reversible controller from Castle Creations to test (provided for review) and here's a good test. I have bought a heap of Deans connecting bars which have around twice the cross sectional area of the 12g wire and are silver plated.

Note that with three packs of 10 cells in Hull-2 I have the same number of cells as the later Hull-1, just configured differently, so the battery box will need to change shape.

The GP3300 (July 2005) 10 cell battery pack drawing

The connector on any battery pack should never be a male or plug type connector with exposed pins, it should always be a socket, or you risk fire or possibly explosion if they accidentally short out!

GP 3300 mAH cells and the latest experimental 12 cell battery using Deans Pro 2.0 bars.

You can buy special clamps to hold battery packs together while you solder them but I find elastic bands and pieces of cardboard works OK.

You need at least an 80 watt good soldering iron to solder to battery cells and you also need to be quick. Manufacturers DO NOT recommend soldering directly to cells but there are thousands of people doing it! Use some fine sandpaper (NOT steel wool) to roughen the terminals first and use rosin cored solder, preferably 62/38 or 63/37 Tin/Lead. Not sure what the Europeans will use due to RoHS (no Lead allowed) probably some Tin/Silver alloy.

Q. What will happen if you use steel wool? (Derrr!)

The latest 12 cell battery pack showing the size of the heatshrink tubing to use, cut the tubing 1/2" longer than the pack on each end as it does shrink in length a bit.

Mark your packs so you can identify any possible charge / discharge issues later on. I also make a hole in the middle with the soldering iron to put a temperature probe in during charging.

And of course we need bigger battery boxes again! This time I made three separate ones so I can distribute the weight around in the hull.

October 2005

These IB3800 sub C cells from Intellect are being talked about on the car racing forums as being better performance than the GP3700 sub C cells but quite frankly I would be happy with either type and a bit of competition seems to be making the GP3300 cells somewhat cheaper as well (and they are still great too with only marginally less capacity). All the racing cells are generally "zapped" by suppliers with a huge current pulse to increase the cell voltage by reducing the internal resistance, these zapped cells are usually the highest voltage cells selected from any particular batch and then zapped and are sold at a 20 - 30% price increase over unzapped lower voltage cells. So be careful where you buy them and remember, you get what you pay for! Again these cells are designed specifically for high discharge currents of up to 10C plus (38+ amps).

December 2005

Intellect has quickly established its position in the top model car racing competition level with their earlier release of the IB3800. To further elevate the performance of high-end RC racing batteries, Intellect has succeeded in breaking the 4.000mAh barrier, and has unleashed the brand new IB4200 Ni-MH Sub-C cell. The IB4200 cells show a MINIMUM AVERAGE VOLTAGE OF 1.200 at 30amp discharge! Needless to say that the performance of these cells, with its enormous capacity of 4200maH and 1.2+ voltage, surpasses any expectation.

October 2006

I have just ordered some GP 4300's to make up a 12 cell pack to try in Hull-2 from www.maxamps.com

Maxamps sell various battery configurations on E-Bay on a regular basis, I have bought two lots of 6 cell side by side packs so that I can easily join them to make a single 12 cell pack. I want to compare the duration to the GP 3300's. These are the latest in Gold Peak cells, should give 1.26V at 30 Amps. Maxamps also have some ownbranded 4400 mAH cells.

While we are on the subject of cells and batteries, from my research, unless you have specific knowledge about battery cell chemistry and charger technologies and you have lots of past experience, I would not recommend using any sort of Lithium cell in a high and potentially uncontrolled discharge current situation! Most hobby shops seem to agree! However they are fine in a fully controlled situation like a mobile phone or a laptop. I have even seen the experts overcharge a Lithium pack with a smart charger, it happens!

Also from a pollution standpoint, (and if you like fish) Lead, Lithium and Cadmium are not very nice substances to use in a marine environment. Nickel Metal Hydride (NiMH) batteries are possibly the least polluting of all the currently available battery cell technologies and according to the marketing hype can be re-charged up to 1000 times if treated correctly.

The European Union (EU) has a Directive called RoHS (Restriction of certain Hazardous Substances). These substances include Lead (in Lead Acid batteries) and Cadmium (in Nickel Cadmium or NiCD batteries). This EU Directive should start in 2006 but in 2004 there is another Directive called WEEE (Waste from Electrical and Electronic Equipment) which deals with the recovery, sorting and treatment of non-compliant products. So maybe as a result of these two Directives we may expect to see some cheap Lead Acid and NiCD battery packs on the market.

At the present rate of development NiMH batteries will probably replace the humble Lead Acid car battery within a few years - but that's just my opinion! There is also currently design work happening around the world to replace the 12VDC power system in cars with a 42VDC power system, this is making for some very interesting DC motor control and power MOSFet device developments.

The Latest in Lithium Polymer Batteries - January 2011

Thunder Power (www.thunderpowerrc.com) G4 Series Lithium Polymer batteries are about the latest (available) developments that I have found in 2011 that are generally available to the hobby industry, These batteries have enormous capacities and light weight. I have used a few in recent years and I feel that the lifetime and capacity sustainability in Lithium Polymer Batteries is better even than with NiMH batteries.

There are a number of Lithium Polymer developments coming that I have read about using nano technology silicon anodes etc. which promise anything up to a 10 fold increase in capacity but it will take some years for these developments to make it to commercial reality.

Thunder Power RC has been a world leader in the advancement of

commercially available Lithium Polymer (LiPo)

technologies, continuing to set industry leading standards in performance,

capacity and reliability.

Thunder Power RC 4th generation (G4) chemistry offers a realm of power delivery, cycle life delivery and ultra fast charge rate capability never before seen or experienced. These cells claim to be built using the highest quality Japanese-made materials, including the latest in super-fine substrate (nano) technology to offer the lowest possible internal resistance (IR) and vastly superior power, capacity and cycle life delivery. The result is that G4 series batteries offer up to 40% more power and 6 times more cycle life delivery than previous generation LiPo batteries. Plus they can be ultra fast charged safely at rates up to 6C with no discernable loss of power or cycle life delivery. These features, coupled with their industry leading lowest weight and highest energy density plus their proven ability to deliver up to 300+ cycles with no loss in power delivery offers long-lasting value and performance that equates to the lowest cost and most performance per cycle in the market today.

Available with continuous discharge rate capabilities from 20C to 65C, in capacities from 250mAh to 8000mAh and in configurations from 1S 3.7V to 10S 37.0V, therefore a G4 series battery is perfect for nearly every imaginable application. Plus they are backed with an industry leading full 2 year warranty and 2 years of 50% off damage replacement program coverage.

To get the best performance and lifetime these batteries MUST be charged using a suitable charger, and in multiple cell batteries, using a cell balancer to make sure that the individual cells within the battery are properly cared for.